Laser Displacement Sensors

Whether logistics or production: the degree of automation is constantly increasing, and so must the coordination of various process steps. Many of the resulting situations can be formulated as questions about positioning or measuring distances:

Positioning: The question of the exact position of an object is relevant, for example, when a machine has to transfer an object to another machine. This can be a pallet in a logistics center that has been set down and is now to be picked up, or a workpiece that is fed to the next machine in a production line.

Alignment: If the distances are measured in several dimensions, then the alignment of an object can also be derived from this information.

Speed: If the distance measurement is repeated over fixed time intervals, the speed of an object can also be determined on the basis of the changed distance.

Material consumption: For rolled material, such as foils or sheets, the remaining amount of material can be determined by measuring the changing distance between sensor and roll surface. The data can also be used to control subsequent processing, for example if material has to be removed from the roll at a constant angle despite the continuously decreasing outer diameter. At the same time, the process can be quickly adapted to different material thicknesses.

Filling level in tanks or silos: Consumption or storage level of liquids, grain or granules can be determined with the help of laser distance sensors via the distance to the material surface. With repeated measurements, statements can also be made about increase or decrease rates, which, for example, makes it possible to identify deviations from the norm in the process.

Workpiece length: A production step can deal with incoming material of variable length (e.g. pipes or beams) if the respective length is determined in the process with the help of a distance measurement.

All of these challenges can be solved with the help of laser displacement sensors.

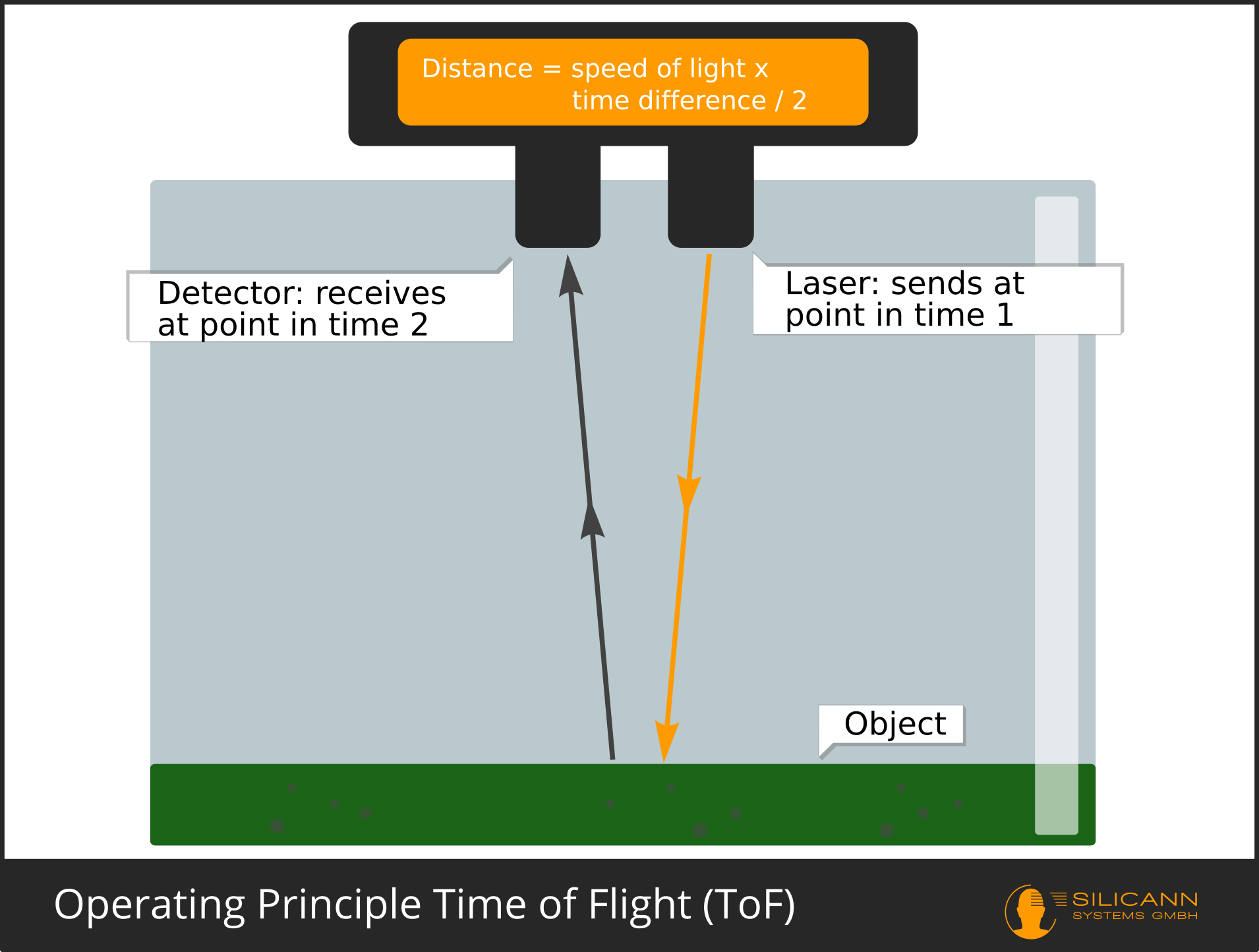

Measurement principle: Time of Flight

Laser diplacement sensors that employ the principle of time of flight actually measure time and derive the distance from it: light waves are emitted and hit an object. They are reflected from the object and the reflected light is received again by the sensor. The distance covered can be derived from the time interval between transmission and subsequent reception of the signal.

The most common name for this measurement principle is Time of Flight, which is why these types of sensors are also called ToF sensors.

We'd love to help you

Please contact us with your particular challenge. Together we'll find a solution that will deliver robust and precise results.