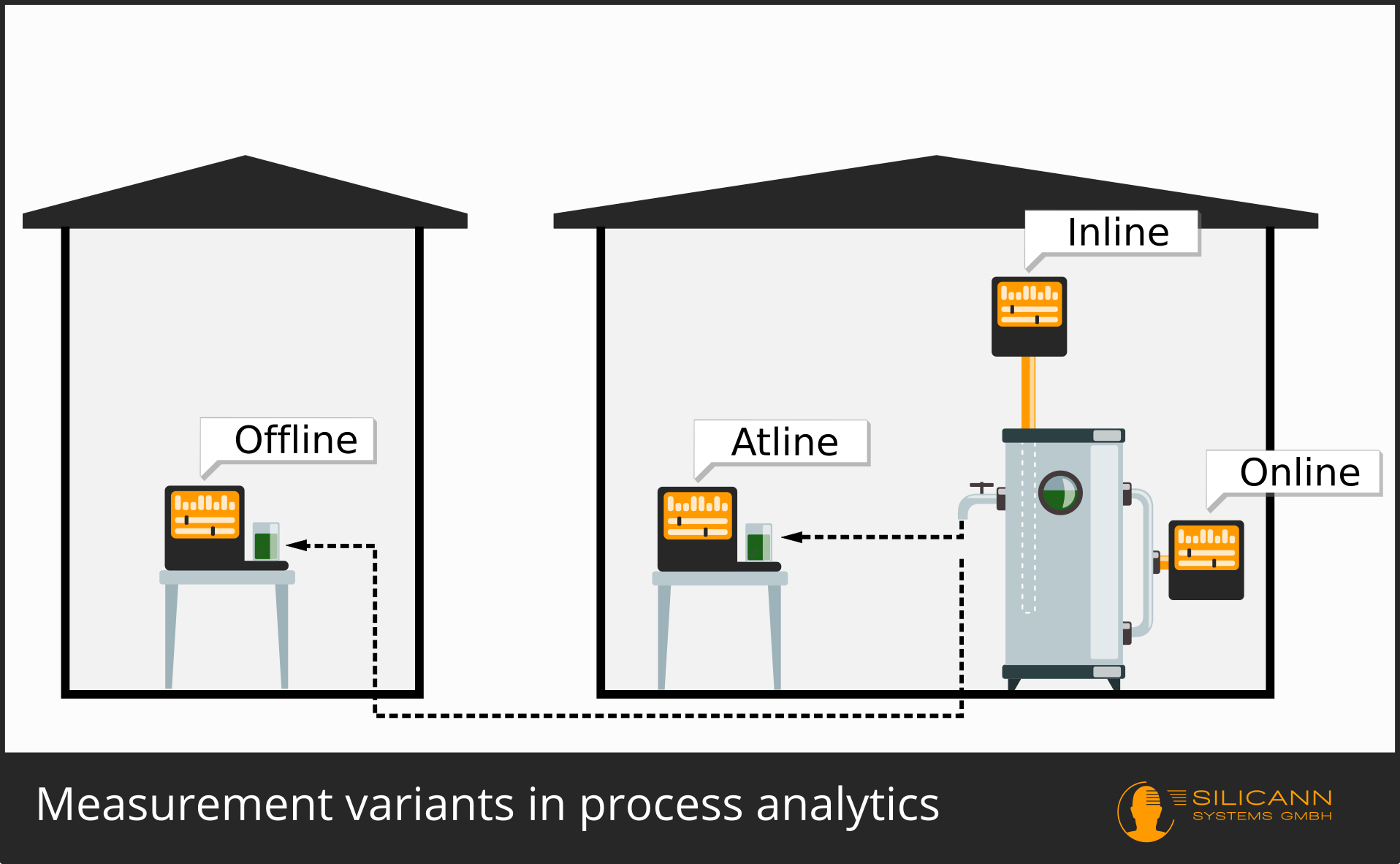

Inline, Online or Atline - Measurement approaches in process analytics

Inline, online, atline or offline - when you have questions about measurement in production, you will quickly come across these terms. Unfortunately they are often used without a more precise definition - or marketing texts suggest they can be used interchangeably.

This article brings light into the dark and explains the differences and respective advantages and disadvantages of the different measurement approaches.

Without process analytics manufacturing drives blind

Industrial manufacturing is highly automated these days. In many fields of manufacturing machines have almost completely replaced people. They often are faster and cheaper, and they can perform tasks that would pose health risks to people or that simply are beyond the limits of what is physically possible for a human.

With the removal of the human factor, however, its intelligence in quality control directly in the manufacturing process is also lost. This is now the task of process analytics (or Process Analytics Technology, PAT): The individual steps of the production process are monitored with the help of suitable measuring technology.

Inline, Online, Atline, Offline: The distance to the manufacturing process makes the difference

No matter whether chemical processes in the reactor or automated production at the manufacturing line: These terms describe how far away the measurement takes place from the scene.

Inline measurement: directly in the process

With an inline measurement, measurements are taken directly in the process. This can be, for example, an optical sensor that inspects whether the coating on a component has been applied correctly, or a spectrometer with a measuring head hanging directly in the reactor. Inline process analytics usually takes place continuously, i.e. as long as the production process is running, automatic measurements are made over and over again. Automated decisions are very often made based on the measurement data: If, for example, the coating on the component does not conform to the standard, the part is immediately rejected. The great advantage of inline measurement is that it measures almost exactly what is taking place in the process, even exactly at the point in time when something happens. However, the production processes are often extremely fast, which means often only a fraction of a second is available for a single measurement.

Online measurement: at a branch of the process

An online measurement also usually takes place continuously. Here, however, measurements are not made directly in the process, but rather in a built-in branch (or "bypass") into which samples of the substance to be measured are automatically fed. This is done, for example, when the measuring device cannot withstand the tough conditions that are encountered directly in the process (e.g. high pressures or temperatures). In such cases, online measurement setups make continuous measurement possible - only they no longer measure exactly what takes place in the process: The material to be measured may behave a little differently than under the high pressures existing directly in the process.

Online measurements also enable measurement methods that would not be possible as an inline variant. For example, reagents can be added automatically to the sample taken in order to then check for a color change. These reagents should of course not flow into the end product, which is why inline measurement with reagents is almost never possible.

However, some time also passes during this process. This means in the worst case scenario defective material has been produced for several minutes bevore it is possible to react to the error.

Atline measurement: In the lab next door

Sometimes an online measurement is difficult to implement economically or simply isn't technically possible. Then a person has to manually take a sample and check it with a laboratory measuring device. If this measuring location is still close to production, for example if the lab is in the adjoining room, this is called an atline measurement.

Atline measurements enable the implementation of more complex measurement processes: Samples can be prepared in practically any way, and there is enough time for the measurement process to take place. In addition, the measuring device can be unconditionally optimized for precision because it doesn't take place in the harsh production environment but rather in an air-conditioned laboratory.

This precision is bought at the price of a long time lag between the sampling and the availability of the measurement result. Of course this long period also means that production problems can only be recognized after a long time.

Atline measurements are therefore often used less for the direct control of internal processes in process analytics, but rather for external documentation of standard conformity: Many ISO standards describe the exact processes of atline measurements, with the help of which, for example, it is proven that none heavy metals are present in the processed milk at a cheese factory. Such measurement protocols are then supplied with the sale, for example, and document the quality of the product delivered.

Offline measurement: in a third party lab

If the production site does not have the capacity for the necessary measurements, the sample must be sent to an external laboratory: an offline measurement takes place. It will therefore often take several days for the result to arrive. This measurement variant is thus largely decoupled from the production process. They can be used, for example, for random checks on substances that come from a supplier and are only added to production at a later point in time.

Conclusion

The different measurement variants inline, online, atline and offline differ considerably, especially in the time it takes for the measurement result to be available. While inline measurements are usually calculated in milliseconds, manual measurements can take hours (atline) to days (offline) .

On the other hand manual work in the lab often enables both higher precision and different techniques than would be possible directly in the manufacturing process.

The ideal measurement approach therefore cannot be determined across the board, but depends on the situation in production and also on the state of what is technically possible, as well as on the standard specifications required for a particular industry.

The trend, however, is clearly moving in the direction of continuous inline measurement.